Dear community,

From now on we’ll be using this thread to post project updates.

As kindly reminded by @biomakers_lab in their post, this is part of our responsibilities towards the GOSH 2022 Collaborative Development Program.

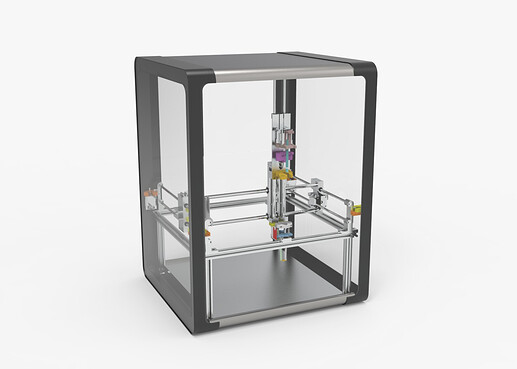

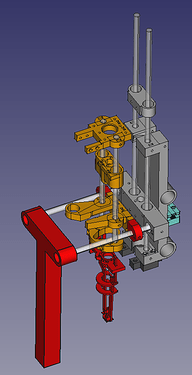

Link to the project presentation: Pipetting bot - Project presentation

Activities summary

-

2022/03/17 to 2022/05/05: During this time the award process took place.

- Initial award notice (2022/03/17) and worksheet sent (2022/03/31).

- Due diligence checks done (2022/04/16)

- Award agreement signed between with GOSH Inc. and FUNDACEN (2022/05/05).

-

2022/05/24 to 2022/06/24: Funds become available and the shopping begins!

- Make a shopping list / BOM (#13) · Issues · Open Lab Automata / Pipetting Bot · GitLab

- Buy and pick up components (#12) · Issues · Open Lab Automata / Pipetting Bot · GitLab

- Shopping list, presupuesto y compras (#3) · Issues · Open Lab Automata / Pipetting GitBuilding Docs · GitLab

- Make BOM / Import GitBuilding PartLibrary from CSV (#4) · Issues · Open Lab Automata / Pipetting GitBuilding Docs · GitLab

Shopping list complete (files here) and items purchased.

Shopping list complete (files here) and items purchased.

-

2022/06/24 - Present: Work on assembly documentation

- Repositories moved from GitHub to GitLab.

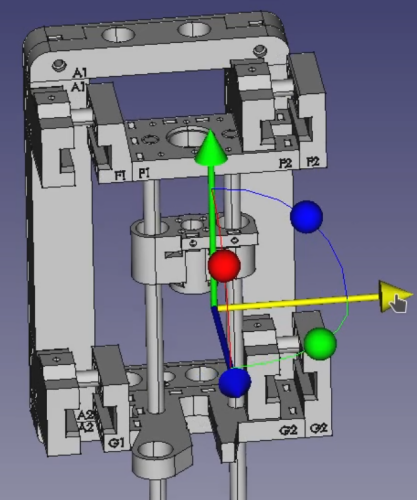

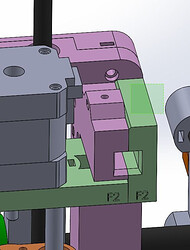

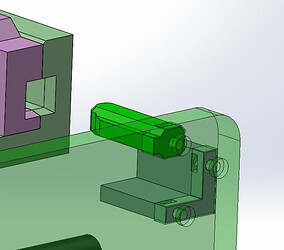

Major repository reorganization and migration of leftover TinkerCAD models to FreeCAD. Now 100% free.

Major repository reorganization and migration of leftover TinkerCAD models to FreeCAD. Now 100% free.- List of awesome OSH toolchanger projects: Toolchanger projects list (#1) · Issues · Open Lab Automata / Pipetting Bot · GitLab

Documentation layout in GitBuilding.

Documentation layout in GitBuilding. Started documenting the making process.

Started documenting the making process.

-

2022/06/03 - 2022/07/15: Search for collaborators!

- Prepared the open collaboration call: Prepare and publish "collaboration calls" (#8) · Issues · Open Lab Automata / Pipetting Bot · GitLab

Posted it in the forum.

Posted it in the forum.- Shared the call directly with potential candidates: Pipe (2022/06/05), Pachu (2022/06/12), INGIA S.R.L. (2022/06/03), Renan from reGOSH (2022/06/26), and others.

- Interviews / meetings with potential collaborators:

- Pipe (2022/06/06).

- INGIA S.R.L. (2022/06/28).

- Solomon @Solioboni from OHM (2022/06/29).

- Renan @renan from reGOSH (2022/07/01),

- David @Glyxon (unscheduled)

So far so good ![]() .

.

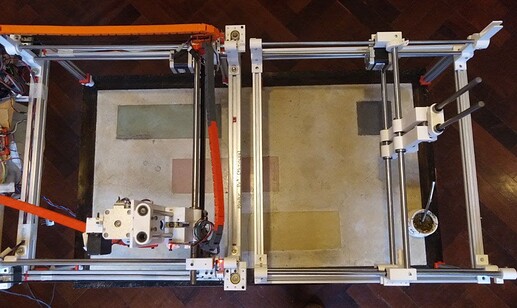

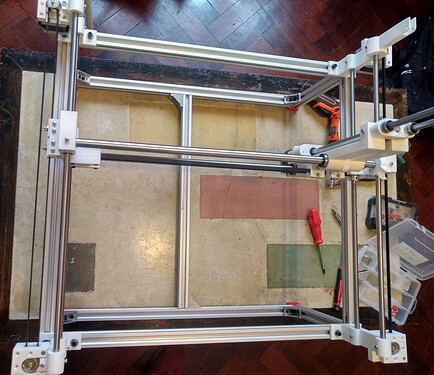

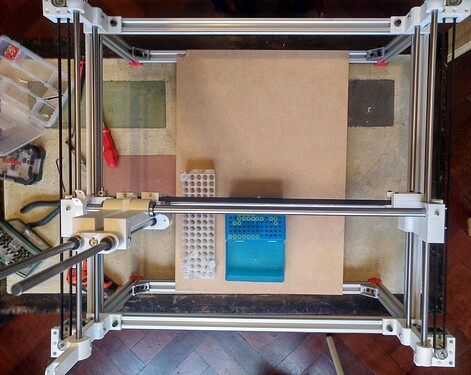

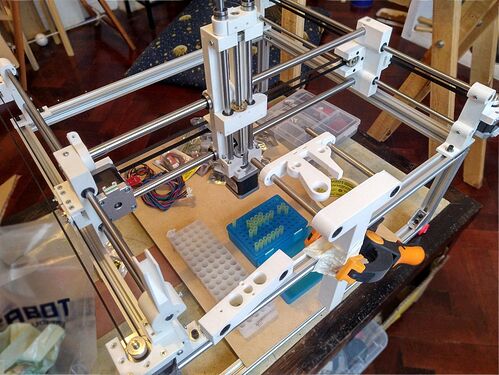

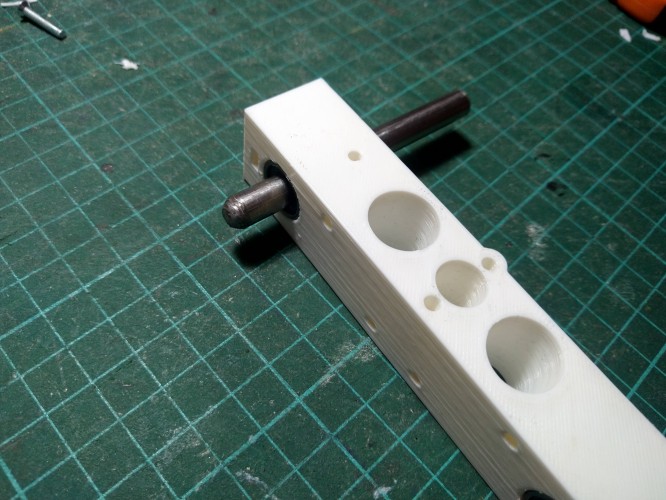

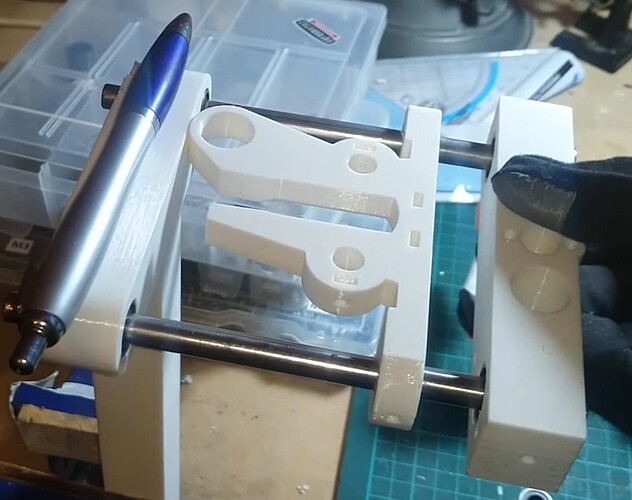

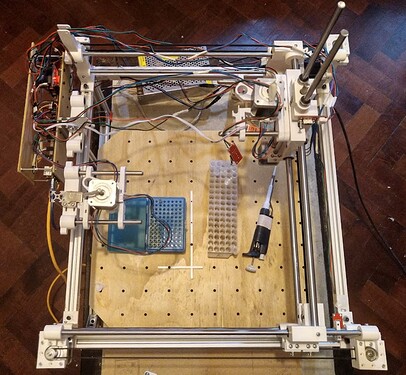

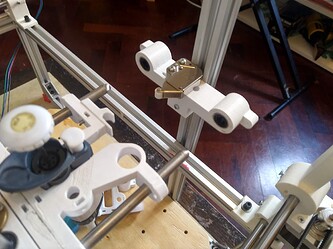

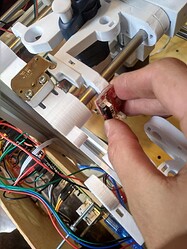

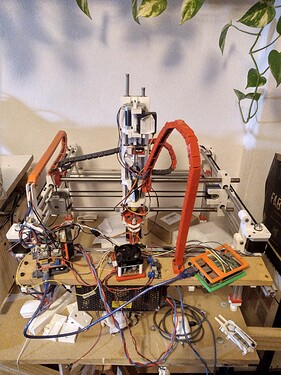

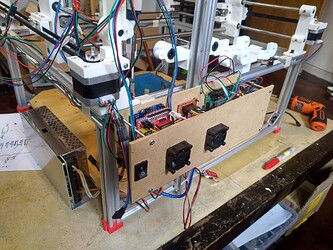

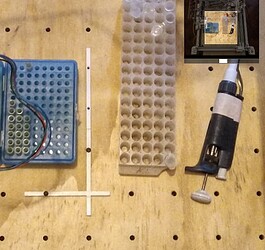

Photo album!

I’ll be posting pictures to a photo album in case you’d like to check out the latest photographic updates.

Parts purchased and printed :3

Future updates

Future updates will be shared as a reply on this same thread, hopefully on the following subjects:

- Decision on collaboration.

- Build videos and full documentation for the final prototype.

Plan deviations

- Budget change: a budget redistribution was requested on the collaboration items was approved, merging the budgets into one collaboration for the hardware tasks. The software tasks will be absorbed by yours truly.

- We are apparently behind schedule, since work on projects was to happen between the 1st of April and the 5th of July, according to the program’s timetable. The estimated delay is around 1 or 2 months, and is mainly due to administration tasks and shopping taking longer than expected.

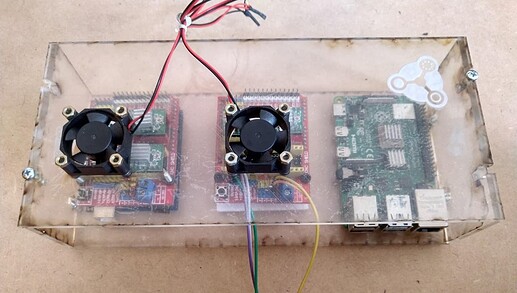

- There are no Raspberry Pi 4 boards available in the local market, due to global supply problems. I am using a spare board for now, but if this continues we may be forced to rethink at least a part of the electronics/control system.

- The future of GitBuilding is uncertain. Even so, we remain committed to use it to document our entire project, and I want to thank him enormously for his guidance, and for the incredible work he has done. Thank you @julianstirling

.

.

Thanks!

Progress would have been impossible without the help of the GOSH community (mostly behind the scenes), and many friends helping out at each step; from suggesting collaborators to finding the right fiscal sponsor!

Stay tuned for the next update (?) ![]()