Hi GOSH community,

I’m a student from Kerala, India, working independently on an idea to reduce post-harvest losses in fruits and vegetables, especially tomatoes.

Here, ambient temperatures often reach around 34 °C with high humidity, and small farmers have very limited access to cold storage.

I’m still early in this process and honestly figuring things out as I go, so I’m posting this for peer review and guidance, not as a finished solution.

Core idea (what I’m actually trying to test):

The main thing I want to explore is a control idea I’m calling VERP (Variable Ecosystem Regulation Protocol).

The basic thought is this: instead of holding storage conditions at fixed setpoints, could we let the system stay passive most of the time and intervene only when biological stress indicators appear?

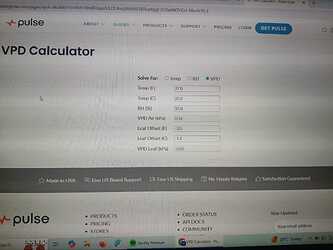

In EcoPod, moisture dynamics, especially vapor pressure deficit (VPD), act as the primary signal, but they are not the only factor. Temperature smoothing, surface moisture state, and time-based thresholds also matter.

So while VPD suppression is central, the larger question is whether feedback-based, minimal intervention works better than constant control for post-harvest storage.

Fig 1: Mathematical modeling of VPD suppression thresholds.

EcoPod (as a testbed for VERP):

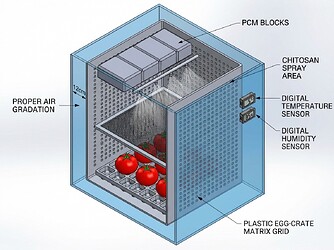

EcoPod is a conceptual, passive storage chamber meant to test this idea, not a finalized device.

Current thinking includes:

-

Double-wall structure (around 12 cm gap), intended as a stagnant air layer for basic thermal buffering.

-

PCM layer near the ceiling, to reduce short-term temperature spikes and allow gentle, gravity-driven cooling without fans.

-

Chitosan-based mesh or interface zone, explored as a way to introduce mild antimicrobial moisture only when triggered, not continuously.

-

Egg-crate style base, to reduce contact-point rot and allow air and moisture to equilibrate around produce.

At this point, these are design hypotheses represented through sketches and rough modeling, not a built prototype.

Fig 2: 2D visualization of the double-walled thermal buffer.

What I’ve simulated or reasoned so far:

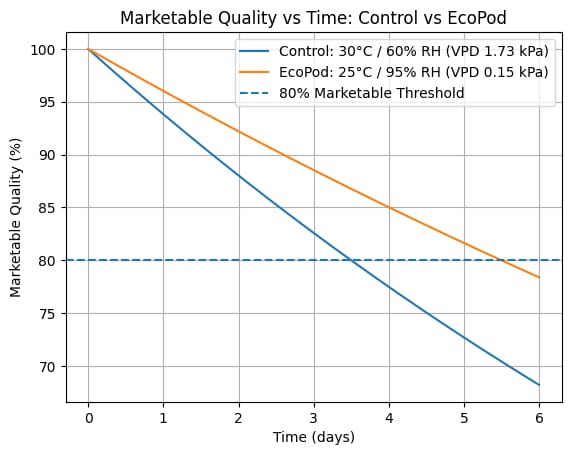

Using basic VPD and transpiration relationships, I’ve done simple simulations suggesting that maintaining very high relative humidity (around 95 percent) could significantly reduce moisture loss compared to open storage.

These simulations are not meant to prove performance, but to test whether the VERP idea is physically plausible in a passive system.

I’m very aware these assumptions need correction and validation.

What I’m actually seeking help with

This is where I’d really appreciate peer input:

-

Thermal logic

Is a roughly 12 cm stagnant air gap meaningful as a thermal resistor at around 34 °C ambient conditions, or would reflective layers or baffles be more realistic in a passive setup? -

High relative humidity sensing and feedback

If VERP depends on thresholds, sensor reliability matters. Does anyone have experience with RH sensors such as SHT4x or similar in sustained 95 percent or higher humidity environments? -

VPD behavior in passive systems

Most VPD models assume open or actively ventilated systems. How should VPD be treated when produce itself is the dominant moisture source in a mostly closed volume? -

Failure boundaries

How would you define a safe operating window where moisture stress is reduced without tipping into microbial risk?

Fig 3: Comparative simulation of produce marketable quality over 6 days. The EcoPod model (VPD 0.15 kPa) demonstrates a significant extension in shelf life compared to standard ambient conditions (VPD 1.73 kPa)

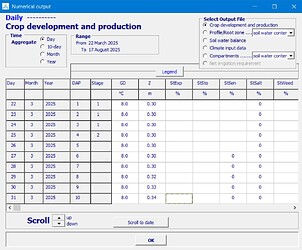

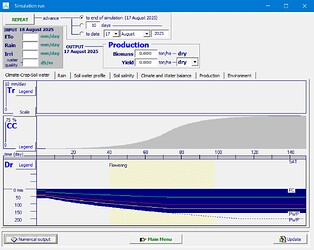

Figure 4: Numerical output from FAO AquaCrop used to establish baseline transpiration stress and canopy expansion parameters for the model.

Figure 5: AquaCrop simulation dashboard illustrating the environmental input parameters and biomass development modeling used to inform the VERP logic.

Why I’m posting this here:

I’m not trying to pitch a product or claim a solution. I’m trying to stress-test an idea, especially the VERP logic, before it goes any further.

This is an open, exploratory project, and I’m happy to share notes, sketches, and simulations as they evolve. Critical feedback is very welcome.

Thanks for reading, and thanks in advance for any thoughts, even if it’s “this assumption is wrong”.

— Roze