I know I know, it’s just one less thing to think about when we get there that’s all. If we never use it, not big deal, it’ll just sit in my luggage

@biomurph and I were talking about organizing an SMT soldering workshop (teaching people to use solderpaste, stencils, etc.). We are looking for anyone who might want to help, but especially any Shenzhen locals (or anyone arriving early) who might have access to tools and/or would like to help organize kits.

Some specific things we are trying to figure out:

- How feasible it would be to source parts (components and PCBs) locally. Can we order ahead of time and have them delivered?

- Does anyone have access to a hotplate, hot air gun, reflow oven that we could borrow during GOSH?

If you have any suggestions on any of these or if you are interested in helping out, let us know. As for what PCB design to use, I was thinking it would be cool to build these Feather M4 boards by Adafruit. The BOM is ~$5 and they use the awesome SAMD51 chip. This is a great board for playing around with Micro/CircuitPython (which could be a nice follow on workshop).

we can get everything in less than 24h. also pcb’s no problem. http://www.hqpcb.com/

i can organize everything else. hotplate…

as a workshop, maybe it’s more fun to reflow something more simple, also saves us costs…

something that blinks and beeps according to some sensor? maybe programmable…

http://forum.openhardware.science/t/gosh-workshop-modules-under-development/

I definitely hear what you are saying. Part of me is worried that the Feather board is too complicated and has small parts (i.e., 0603, QFN).

But I also think micropython makes the software side so much simpler/easier/more accessible and I feel like this is the way things are headed… As for cost, $5 isn’t nothing, but it’s pretty cheap compared to most Arduino-type dev boards and I would argue that this board is probably the best bang for your buck right now.

So there are trade-offs, but maybe it doesn’t have to be an either/or. We could have a beginner blink-and-beep circuit and a more advanced dev board circuit (which could also be used to teach about flashing a bootloader, incorporating an MCU into your own design, intro to Micropython, etc.). What do other people think?

yip let’s make many! diversity of designs and uses, can not be put into “One board to rule them all”. let’s share skills to redesign, manufacture, reflow. not just do one thing, that was pre-design by “us”.

m

@dusjagr Yes, I totally agree that more is more.

@ryanfobel put together some documentation on the Feather M4 clone that we’re looking to make.

Here is his octopart BOM

https://octopart.com/bom-tool/iG2ytmPM

and his repo with the board files [KiCAD]

I also think that this board is a great tool to have.

Let’s change the silk to say something about GOSH 2018?

redesign and contribute is more than changing the silk… didnt you just have this experience with @gaudi

I agree. Ryan and I are trying to keep the work as simple and useful as possible. The goal is to have a mass-produced part, and use production processes (stenciled solder paste, production process, etc). The Feather M4 is a really useful tool in its own right. That said, I can see using the PPH space that Adafruit has provided and using it to add sensors, or at least lands for sensors of some type.

Yes. I was in an impossible situation having to produce a working system for the BioHacking Village, and the OpenDrop was immediately available. As it was, I only had time and resources to chase down all the EOL and out of stock listings on the BOM.

Totally agree with this. The goal is not to make an original board for this workshop, but I do think it is useful to convert this reference design to KiCad and write up documentation re: flashing the MCU bootloader, etc. This should make it easier for other people to design new OScH projects around this awesome chipset (and using the Feather ecosystem in general).

I think it’s a great idea to add something in the proto area to customize it further. Maybe some Grove or Qwiic ports for protoyping with other sensors/actuators? Any other ideas?

Well, we have two sides of the PCB…

Looks like Qwiic system is only I2C, Whereas Grove has multiple protocols for their connections.

Stick with Grove, and have two different connection options? Mix and match?

Great idea!

Hi @leosehn! Yes I’m still interested!

Yup, the invitation to MakerBay is really for the people who land in HK, so on your way in to GOSH, or on your way out, back home. For electronics and hardware, there is definitely a lot more to see, do, shop in Shenzhen, but i think you guys will still appreciate to have a friendly place in Hong Kong  To save you time looking for our address when you land:

To save you time looking for our address when you land:

https://www.makerbay.org/pages/contact-1

Oh, we have a reflow oven and a good collection of components.

There was a lot of interest last year in doing a surface mount soldering workshop (@kaspar @gbathree @biomurph @kina.smith @dusjagr). Anyone else interested in helping to organize something like this and/or have any good ideas for a simple/cheap board to make (e.g., GOSH2018 badge?).

The Adafruit ItsyBitsy M4 is a pretty cool little SAMD51 dev board (the SAMD51 is the successor to the popular SAMD21) that can be made for ~$5. It’s plenty fast and has lots of flash/ram for running CircuitPython, which could facilitate a nice follow-on activity/workshop.

I would be down to help make this happen.

I have a J-Link programmer (assuming that’s what we need to bootload the SAMD51)

I can bring soldering tools… how do you propose to mount the QFN?

When I do these kinds of prototype builds, I go through PCB Pool. They provide a free stencil…

We would need a reflow heat gun… I bet Shenzhen has a pile of them somewhere…

Re-Routing the Feather M4 so that it will accept Grove connectors. I went with I2C and Analog, figuring that they are the most used circuits in the Grove environment. Here’s a link to the work that I did based on @ryanfobel work.

https://github.com/biomurph/Feather-M4-Express-clone.kicad

The board layout is the one with GOSH in the title. I could not get KiCAD to produce a usable .net file, because the one from my fork is ‘legacy’. After fighting it for a few hours to get the GND connections to be happy, I think I just need to widen the board a bit to make the analog connections…

Anyhoo, just posting progress. If anybody has feedback on the re-design, please post here or on the issues tab of my github.

I can help and am arriving on the 3rd. I put my name down on the spreadsheet.

EDIT: I have been thinking: maybe we could try and let people pick an existing open source hardware project that they want and help them order and assemble it. If we can turn PCBs in 24 hours and get components from HQB, seems like a great opportunity. What do you think @ryanfobel @biomurph @dusjagr @gbathree ?

That would be fun and really helpful for someone in the right place in the process…

I have a project that I’d like to bring (don’t want to take resources from others, but if we’re looking for fun stuff I’m happy to bring it)! It’s something we’ve been thinking about working on that feels kind of like a no brainer, soil related. Making a soil penetrometer that was also a soil moisture sensor. There are applications in ag and arboriculture, and it’s honestly very doable in a hackathon one day kind of setup. We’d need just basic stuff (resistors, wires, soldering, maybe a few minor parts), though it’d be nice to have access to a machine shop (nothing complicated, but we’d probably want to machine the stainless rod and possibly tip)… Maybe could even do it at X Factory when we visit.

I am interested being part of it. I am landing in the Morning of on 8th at Hong Kong.

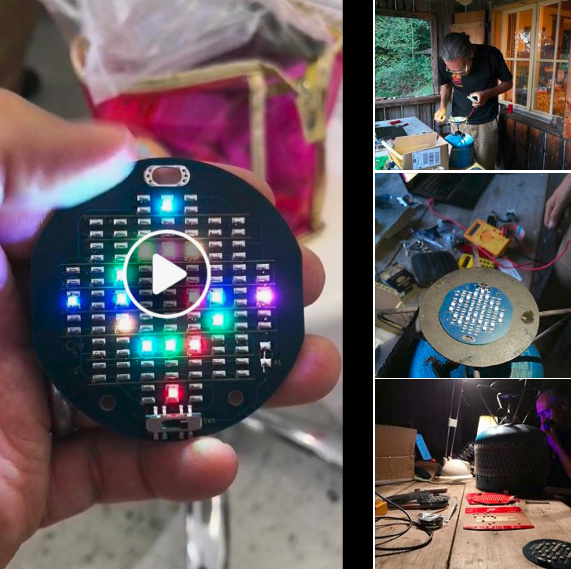

I got 6 of the Feather M4 clones that have two Grove connectors added to them (I2C and Analog).

I also have a stencil and extra parts from this project that I did for OSHWA Summit schwag last week

Might be a fun thing to add to the pile of quick turn projects. I’ll bring the parts.