Dear community!

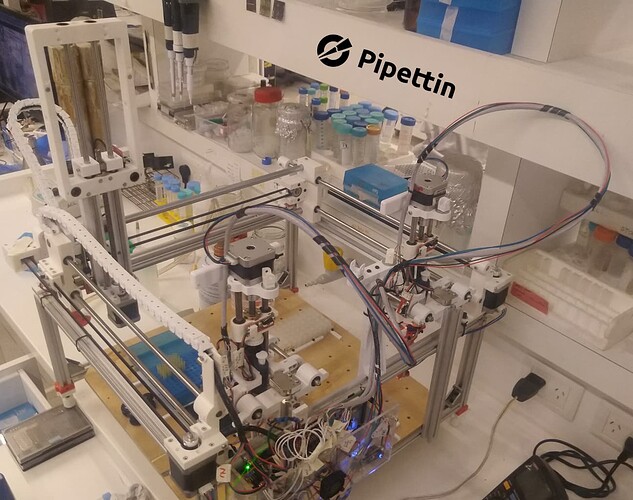

This is a thread for updates on the “pipetting bot” lab automation project, funded by GOSH’s CDP.

Here is it’s current status: 2023/01/18

A contest is going on to name the thing. Participants may post proposals below, and become eligible for pizza awards. For reference, they must surpass TIPMASTER 2000 and MAZINGER in overall coolness.

Collaborations for round 2

In this opportunity, collaborators supported by the CDP will be working on two fronts:

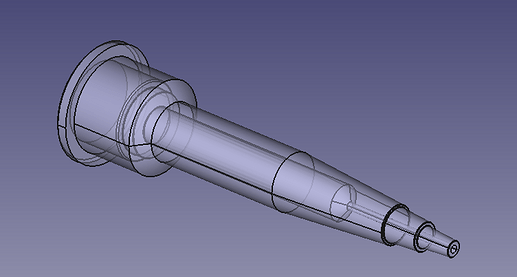

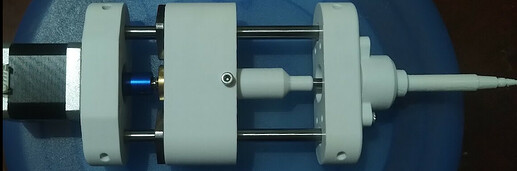

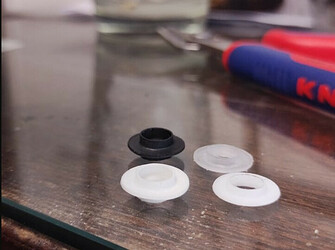

- Hardware: making electronic micropipettes for the robot.

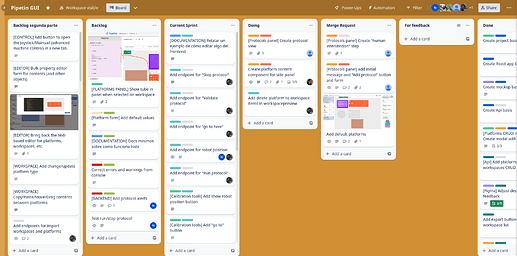

- Software: refactoring the GUI on React.

These tasks correspond to by Bruno Serrentino (mechanical engineer), and Fiqus (software coop.), respectively.

Bonus collabs!

Some very nice collaborations are growing around lab automation in general:

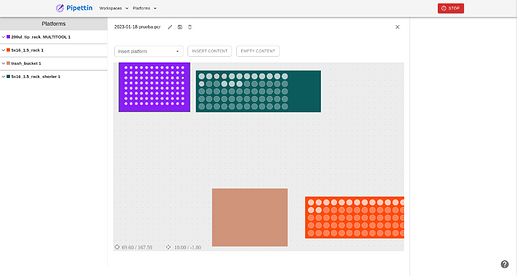

- Friendzymes’ colony picker will play really nice with our tool-changing platform.

- Join the Discord!

- PyLabRobot’s hardware-agnostic protocol programming framework.

Thanks to Jeremy, Scott and Homer (FZ) and Rick (PLR) for the openness and the work so far.

Plan deviations

A lot of effort has gone into planning an integration with Opentrons’ software stack.

After many emails with several devs, we found that working with PLR is the better option for short-term interoperability. Which means that using OT’s protocol designer and/or protocols with out bot is on hold.

However, it does not mean that this and other layers for interops are out of the picture. Quite the contrary!

Eye candy

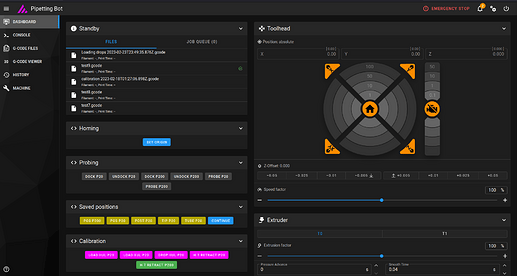

With some initial but crucial help from Jubilee’s lab automation folks, I eventually got Klipper doing everything the project needs to do some pipettin’ (and maybe some yeast paintings on ágar, @laola).

Here is a video, bonus points if you find where GOSH’s logo appears ![]()

Note: to get the project where it’s at, I spent a demented amount of effort spelunking the source of this not-quite-a-CNC firmware. Luckily for my sanity, it paid off. The web apps for CNC control are sick.

Cheers!

As usual, all sources are available here: Open Lab Automata · GitLab