Final project update! 2022-09-11

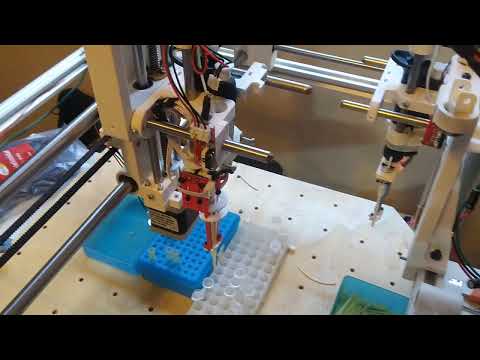

A lot has happened since we started the collaborations since early August, and I am glad to say that a first version of a tool-changing Pipetting robot is ready for testing:

With it, we close a stage of development. ![]()

We are just about to submit our financial and substantive final reports to the CDP working group. Our deadline is on the 14th of September.

Edit 2022/09/22: the substantive and financial reports have been sent.

So what now?

An open source robot has been released into the wild ![]() but our work is far from finished.

but our work is far from finished.

Tool-changer design

Firstly, Pipe’s awesome tool-changer design is still being printed and tested:

- Sources: Files · master · Open Lab Automata / Pipetting Bot · GitLab

- Collaboration log: Issues · Open Lab Automata / Pipetting Bot · GitLab

The one you can see in the video above is an alternate version. This design It was rushed out because remote hardware development is much slower than I anticipated.

With it I was able to refactor the driver software, to support different tools. Pipe’s tool-changer has been printed, and the software is waiting for the first tests!

Future work:

- Test pipe’s tool-changer.

- Make final adjustments.

Baseplate

Solomon’s design is coming along, and will continue well after the deadline:

- Sources: models/modelos_baseplate/solomon_baseplate · master · Open Lab Automata / Pipetting Bot · GitLab

- Collaboration log: Notas de colaboración - Solomon (#20) · Issues · Open Lab Automata / Pipetting Bot · GitLab

As for the tool-changer, the baseplate you can see on the video above was designed as a “dummy” but functional draft. The dummy baseplate and alignment system was needed for software development.

Future work:

- Print and assemble Solomons’ object aligner.

- Make adjustments to the models.

- Discuss the baseplate’s attachment to the robot.

Misc

Varying amounts of work are needed across several fronts:

- Pipe: finish the cable management system (issue 46).

- Pipe: design the electronics case (issue 45).

- Pipe: coordinate manufacturing process of the electronics case with local providers (issue 45).

- Nico: calibrate the pipettes’ volumetric accuracy (issue 44).

- Nico: solve a few EMI noise issues with a driver’s STEP pin (issue 43).

- Nico: use the robot to prepare a few PCR mixes, using the automatic protocol generator feature.

Documentation

The GitBuilding assembly documentation is incomplete, and only covers part of the construction of the cartesian CNC machine.

- Preview here: https://pipettin-bot.gitlab.io/pipettin-grbl-docs/

- Documentation sources here: Open Lab Automata / Pipetting GitBuilding Docs · GitLab

The vast majority of the documentation is still used for development, and is available in several README files. This documentation describes the contents of each directory, explains how each part works, and links to the relevant interacting parts.

Have a look at the READMEs in the main repository! The README files are hyperlinked to each other, and I believe that this documentation can be navigated by anyone interested.

Though documentation is our main objective, writing complete docs requires a lot of time, and I will continue to work on it.

If all goes well, it will be finished before the global gathering at Panama.

That’s all folks!

I’ll reply to this post when the next stage of development starts (hopefully funded by the second round of the CDP; application here).

Feel free to comment and reach out through any of the following channels:

- Forum post or direct message.

- An issue here: https://gitlab.com/pipettin-bot/pipettin-grbl/-/boards/4685246

I’ll be glad to hear your thoughts.

We are very thankful for the support provided by GOSH’s CDP working group, and the Alfred P. Sloan foundation.