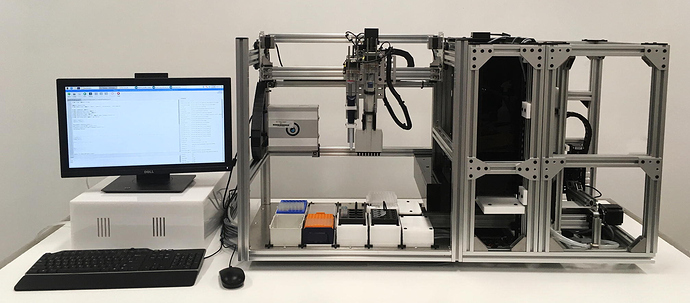

This is a really great case study demonstrating the power of open science hardware. Basically, they’ve adapted an OpenTrons OT-1 into an automated assembly line that can manipulate well plates through a sequence of modular “stations”.

They mention using the original OT-1 vs the newer OT-2 that has been discussed on the forum:

The adaptable coding is why Sebastian chose the older OT-1 model, rather than the just-released OT-2.

“We wanted customizability, and the OT-1 is more do-it-yourself,” Sebastian explains. “With other robots, we’d have to stick to their software and their API [application programming interface], with no access to their protocol parameters. But with Opentrons, we have access to free, open-source software, so we can customize protocols to fit our applications. The tutorials and videos on opentrons.com are straightforward. I generated my own API and changed things to fit our application. It was pretty exciting to see the pipette you usually use manually suddenly dispensing and plunging automatically.”

Also cool to see the positive feedback loops of open hardware tools:

Now he’s paying it forward.

“Opentrons’ vision also inspired us to follow the same open approach,” he says. “All the files for using positive-displacement pipettes with the OT-1, including the 10 lines of code for the revised software script for the ‘get a tip’ function, and the patterns for 3D printing or laser-cutting the pipette holders, are now freely accessible via the GitHub repository.”