Yeah, calibration is really the line that separates the hobbyist sector from the much smaller group of people that are trying to use these little open source controllers for research. The frustrating thing about it is the engineers advice is always the same " buy a more expensive sensor and use their calibration". Which is fine if you are doing a standard task, under standard conditions. But most of the researchers are trying to do things that the sensors were not designed for in the first place - For example, most of our temperature sensor IC failures have been because of pressure at depth… which of course they were never designed to withstand. So calibration is always required.

I’ve been developing a new method for reading thermistors with the Input Capture Unit on pin D8. Micro-controllers count time much more precisely than ADC’s measure voltage, so this new approach delivers more resolution than 16-bit oversampling in about 1/10th the time & power

With the school year beginning we have new instructors spinning up courses around the classroom logger we released in 2019. Some of them are more focused on biology than we are so we did some noodling around to come up with a biophysical monitoring idea that could be done just about anywhere with as few resources as possible.

The result was a ‘Leaf Transmittance Index’ based on readings from an IR LED and the red channel of the indicator LED already on the logger. Although using garden variety LED’s with no real spec introduced several non-optimal aspects wrt frequency & bandwidth, the trial successfully distinguished ‘healthy’ vs ‘unhealthy’ plant leaves where a simple visual inspection could not. Now, before all the bio folks jump on us for all the hand-wavy hacks, and creating a pseudo NDVI with transmittance, rather than reflectance: keep in mind this was meant from the start to be a conceptual proof of concept, rather than a rigorous tool. From a teaching point of view, students would have to create “custom calibrations” for their one-of-a-kind builds & for each plant species - but that’s actually a useful teaching exercise in itself.

Looking forward to hear more from you.

A while back Hackaday posted about using diodes as cheap temperature sensors, but chasing forward voltage deltas in the millivolt range is hard to do with the limited ADC on most mcu’s. Our LED light-sensing experiments demonstrated that timing reverse-bias decay with the Input Capture Unit on an Arduino is easy, and provides high resolution temperature readings from a single diode without any amplification:

I think this will replace our use of thermistors on regulated loggers.

Happy to announce the latest iteration of our DIY underwater housings: with fewer parts and an easier assembly:

Be interesting to see how the students do assembling this new version.

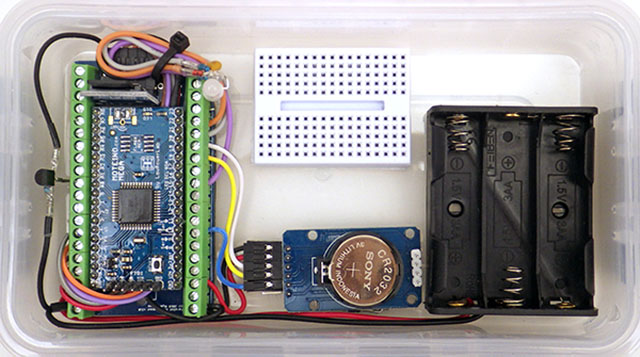

A 1284p based variation of our classroom logger with an RPi terminal board to accommodate the larger footprint. A ‘modules & jumper wires’ approach makes this kind of build variation for research ‘question specific’ prototypes quite easy to do:

Building an ATmega 1284p based Data Logger | Underwater Arduino Data Loggers

Building an ATmega 1284p based Data Logger | Underwater Arduino Data Loggers

Here’s a first look at doing something interesting with an ADS1115 ADC module. I wanted to push it to it’s max settings to see if it’s really usable for research level applications. The answer is a tentative yes, but only at the fastest 860 sample per second speed. And with small signals, EMI is more of a problem than the limitations of the ADC itself. I’m sure that’s not news to any analog hardware hackers out there, but I’m still learning this stuff as I go along.

Covid is making it hard to predict whether students will be in the lab, or working from their bedroom. In response to that uncertainty we’ve done an incremental update to the ‘Classroom Logger’ tutorial from 2019 which separates the soldering steps from the rest of the assembly. Instructors can add/remove those steps as need for whatever confounding situation they are dealing with at their institution this year. Though I have to say, it’s profoundly disagreeable to realize that this years crop of environmental monitoring students might not get the chance to learn how to solder.

Hi Ed,

Nice to see your project is still going on.

I wonder if you’ve considered using the MAX30205 for temperature measurement. This is good to 0.1 degC but only over a very small range, it being a human body temperature sensor. If you’ve tried this I’d be interested in your experience.

Thanks,

-harold

We use si7051 as a cheap 0.1C calibration reference for our thermistors, but that’s the only high accuracy temp sensor I have experience with. After that we go to lab quality nist certified thermometers which start around $250 each.

Hoping to spend time this winter updating some of our Arduino based prototypes, and many will need real-time output. With I2C OLED’s getting so cheap lately, there’s no reason to squash it all onto just one display

We’ve been producing Excel tutorials to support Dr. Beddows students in Instrumentation, & Hydrology courses. Where those overlap with material in the Cave Pearl project we post them to YouTube. Two that might be of particular interest to the GOSH community are:

Derive empirical fit constants with Excel’s trendline

Using Excel’s Fast Fourier Transform tool to derive a tidal frequency spectrum

In our continued effort to support STEM instructors we’ve developed an even simpler 2-module data logger that can be assembled in about 20 minutes and runs for more than a year on a CR2032 coin cell. It stores readings in EEprom memory and the data download is handled through the Arduino IDE’s serial monitor window. This may well be as minimal is it is possible to get with cheap eBay parts and still have a capable data logger that environmental monitoring students can modify and reprogram for their final projects:

Amazing to see news on this project since the first post back in 2018!

Thank you @TheCavePearlProject for sharing these updates.

Thank you @TheCavePearlProject for sharing these updates.

My personal interest is in motion-triggered camera traps for wildlife observations, but I think I can learn lots from you in terms of rugged/weatherproof/waterproof casings.

Posted a general overview of how to make your electronics more water resistant, including recent updates to the PVC housing system we developed. The way we oil-mount pressure sensors might be of particular interest to people working in marine environments

I know these janky installations will have the weather nerds out there inhaling through their teeth, but it’s worth noting that we made multiple attempts over the years to do things the ‘right way’ that kept failing to go the distance. Even in a harshest environment critters are the biggest threat to actual ‘boots on the ground’ research - both four and two legged. So our rule of thumb for anything that’s going to last is now: “Make it ugly & make it heavy”

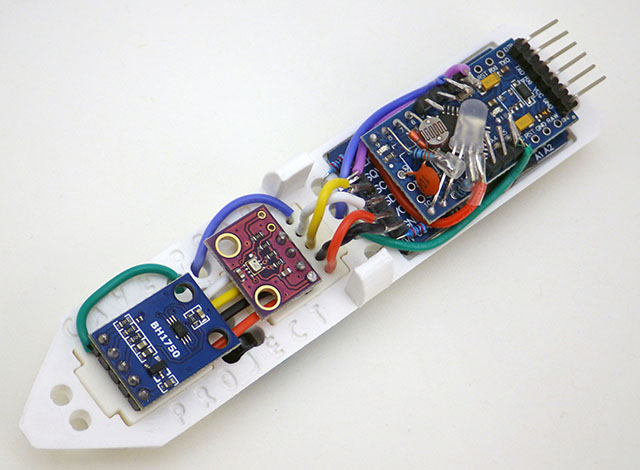

The latest in an ongoing series of build videos supporting Dr. Beddows enviro-sci students who all have to first build the logger(s) that get used for their final research project. These videos also support the other instructors who have adopted our DIY loggers for their own courses. These Falcon tube mini-loggers may well be as minimal as it is possible to go while still offering the flexibility of supporting multiple different sensors. The only limitation is that the CR2032 levels out at 3.0v and runs all the way down to 2.8v before shutdown - which rules out some older sensors like the DS18b20 which has a lower limit of 3.3v. After calibration the NTC has so much more resolution that it’s not much of a problem.

We needed a way to test our little falcon tube loggers and household water filter housings are a good solution as the domestic water pressure range of 40-80psi overlaps nicely with sport diving depths. The internal clearance of that 4x10 filter housing is only slightly larger than 4.5" x 9.5" but could accommodate a good range of other dive computers, lights, etc for testing.

The e360 course required different sensors for each lab, so we tweaked the 2022 2-part model with 3D printed rails holding mini breadboards to provide this flexibility. The software has also been streamlined significantly and people shouldn’t have too much trouble adding other sensors provided you stick to 1,2,4,8 or16 bytes/record and your modules don’t pull more power than the coin cell can provide.

![2-Module Pro Mini Data Logger Build (w 64k EEprom upgrade) [2023]](https://forum.openhardware.science/uploads/db7701/original/2X/e/ee6a377afeea1b53854945b74036dd9aab061607.jpeg)