Rotoforge software is licensed under the AGPL-V3. Rotoforge hardware is licensed under the CERN Open Hardware License-strong

There is a video assembly guide for this printer modification here. There are ongoing blogs and technical details on development of the hardware, physics and materials science involved in this project here.

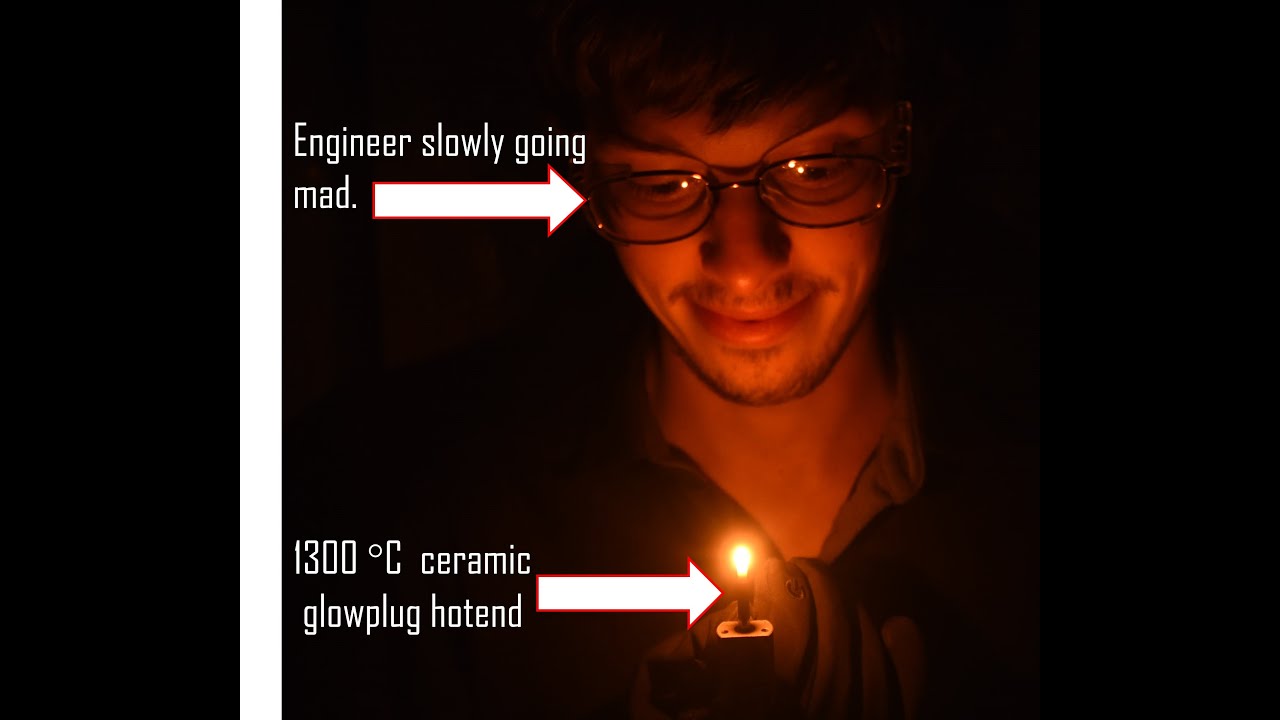

This is Rotoforge, a modification of an FDM printer that uses a combination of friction extrusion / small scale extrusion machining to print metals, plastics and ceramics heterogeneously. In short, a standard 1.4-1.75 mm OD wire of feed material is pushed by a pinch wheel extruder with hardened steel gears into the hollow shaft of a brushless dc motor. At the end of this motor, a “tool” or “die” or “nozzle” is threaded onto the end of the shaft, blocking the wire from exiting. If a hole is drilled in this “nozzle”, and the motor used to spin the nozzle at sufficient RPM, when the feed material is pushed into the spinning nozzle, it will heat up due to friction, and become more flowable(see thixotropy) due to plastic shear(see flow stress) by rotation with the nozzle. When this occurs, even materials like aluminum, steel, glass, and high grade engineering plastics will become extremely fluid and extrude (given the correct conditions) through the hole in the “nozzle”. This principally enables FDM like printing of these materials on a standard 3D printer, given the correct nozzle geometry, and the appropriate RPM and feed rate conditions.

If you would like to download the part files, schematics and documentation including text assembly tutorials and a getting started guide, clone the repository, or download the zipped folder here on github. We also have a youtube channel and a read the docs page.

If you want regular updates on progress from Michael, he has a blog he updates periodically.

For more active discussions we have a discord channel and a subreddit.

for proper data storage on feeds and speeds and other printing and deposition parameters as well as in process data storage we have a zenodo repository:

and we are occasionally active on the GOSH community forums:

Github source repo: