1. Name of applicant(s)

Adrian Filips

2. Email address (or preferred and reliable way of official contact)

adrian.filip@canada.ca

3. What track are you applying to? (select one):

Established Project Track

4. Tell us about your project in one or two sentences

The project is about freeing molecular biology researchers and potentially health providers worldwide from most logistic and financial burdens related to acquiring organic reagents and other resources like antibodies etc. The OScH tool to achieve this is an advanced cell type bioreactor - a chamber where cells are grown under very specific conditions so they can produce reagents, antibodies, vaccines etc. We have already achieved concrete, palpable results both in terms of producing hardware and new genetically engineered organisms.

5. Describe your project goals and how you expect to achieve them

Democratize, increase, speed up and in many cases make possible biology and health research in the world by providing an accessible, affordable versatile OScH tool capable of producing a variety of resources vital for biology and health research.

Make research accessible for people that are part of disadvantaged communities due to discrimination or financial barriers.

Empower people to fulfill their own needs in research, science and health by giving them the tool to create necessary resources.

Molecular biology research requires devices and reagents that make an important part of the costs

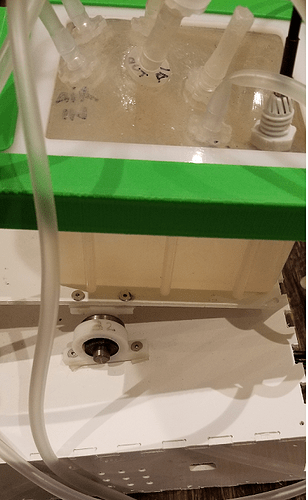

Complete a reusable bioreactor suitable for advanced cell production including mammalian cells

Produce an OScH device capable of producing affordable, quality, reproducible reagents as a turn key solution

Produce a series of genetically designed organisms and device embedded software protocols that would make possible a la carte grow of specific reagents like for instance virus detection kits reagents.

Identify other targets like antibodies and drug delivery systems that can be obtained using the bioreactor

Target to build and field install ideally several complete devices in research labs or health facilities during both phases of the project

Enhance the monitoring capabilities of the device

Install, and train researchers in several labs in specific regions of the world where science is not accessible

Perform multiple types of testing, calibration and characterization of the system

Establish a quality control including creation of traceable audit materials

Creating technical documentation

Publicize the system and inform interested scientists to create a community around the world, similar to other successful project like OpenFlexure

Formed a strong inter-disciplinary team capable of delivering more OscH projects

We employ a nimble agile approach based on several differentiating practices to produce a good quality yet inexpensive OScH:

• We moved the interaction interface to computing devices instead of placing displays, keyboards etc on the device itself. That reduces the complexity and cost while increasing performance and upgradeability

• We created a truly fully reusable device by ensuring all the parts are autoclaveable

• We provided alternatives for using tooling that are under 300$ US which will allow building it in places where more expensive tools (like for instance a laser cutter) is not affordable. We would however provide options for the fortunate that have access to those resources

• We used inexpensive, available electronics on our custom PCB boards

• We created a turn key complete solution so users don’t have to find or create specialized organisms for common products. That is very important due to the cost and availability.

6. Approximately how many people would be working on your project?

The core group will be comprised of 6 people and about 20 or so less involved volunteers, collaborators, helpers and consultants. Many if not most of these resources are experts in their fields and many worked on similar projects in the past and have the necessary experience to bring success to the project. We also have several young brilliant student resources working on the project so the demographics are encompassing

7. Describe how your organization will create and manage collaboration with others.

The development will continue to be performed in a cooperative interdisciplinary team distributed on several continents. We will be using the JOGL platform for most communication and advertising tasks. We are already in contact or know of places and scientists that expressed interest in using our OScH and we want to time that in such a way that we can manage expectations. We will be co-opting further volunteers from groups that are organized by our core members like https://www.meetup.com/biotown/ and Ottawa Bio Science and also use the existing channels like Global Community Biosummit, JOGL etc.

We do in-person gatherings when possible and necessary and we will be present at a Maker Festival soon to be happening. When pandemic hinders direct contact we connect on-line by JTSI or Zomm for meetings, presentations, workshops, demonstrations, hackatons etc

8. Does your project have representation for a marginalized demographic due to factors such as race, ability, place of birth, gender, sexual orientation, socioeconomic class situation or other identification? If so, how?

We do have current members belonging to visible minorities and living in socioeconomic disadvantaged countries. While we are not requesting specific information from our members, our vision goals and activities promote engaging and creating opportunities for economically marginalized, minorities like immigrants and non binary members of the community that have been historically underrepresented. One of our primary goals is to make available our creations in third world countries and poor or marginalized communities where lab research and health is not available or not possible due to prohibitive costs practiced by bio-pharma industry. That way we hope to impact the cycle of poverty marginalization and exclusion and violation of universal human rights. We center our approach on accessibility, diversity, equality and inclusion

9. What resources / infrastructure do you currently have to support your project?

Many of our current core collaborators have the professional skills needed for the project and many of them have maker resources and well equipped workshops including two molecular biology labs. We have full access 24x7 to these resources.

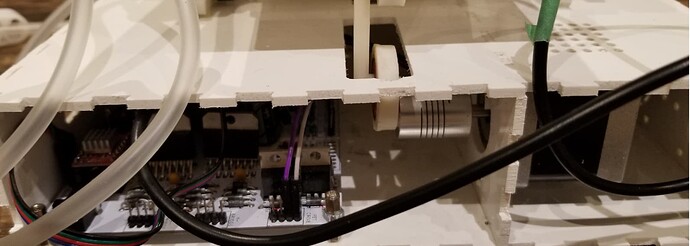

The electronic workshops include current capabilities for population of PCB using both through-hole and surface mounted technologies and we used both for the current prototype boards.

Besides regular mechanical equipment, we have access to laser cutting services and exclusive access to 3d printers, 4 CNC machines, a plasma cutter and a metal lathe.

The full access molecular biology labs are equipped with several PCR machines, centrifuges, orbital shakers, transilluminators, autoclave, electrophoresis apparatus for DNA and vertical gel boxes for proteins, vortex, multiple reagents, consumables and other smaller items.

We want to stress that these resources are dedicated for supporting this project therefore fully available.

Most of our volunteers have University degrees and many years of experience with world leading organizations. Many of them successfully collaborated on makers projects.

10. What will you use the funds for? Describe your budget. List what you are going to spend it on and how.

Raw materials for cases and chambers and tubing etc

Electronic components

Mechanical parts like motors, pumps

Lab reagents and consumables

Additional test equipment

Travel funds for communication purposes

Shipping and packing costs

Consulting with experts to review, validate our decisions and help with very specific issues

A breakdown will be presented as part of question 18.

Please note that substantial funds have already been personally contributed by the volunteers already to reach this stage.

11. How will you share the outcomes your project? What documentation will you provide so that it will benefit the community as a whole? (videos? photos? a how-to?)

We intend to use a multiple method approach or different target audiences:

For makers that have the skills to make things we will publish all the information needed to building the OScH

For biology and health researchers that do not have the skills to execute the builds we will be looking at alternatives like producing or finding producers for kits or even pre- assembled systems

We will create an assembly video.

We intend to use existing gitHub, Google Docs and Slack hosted documentation and develop new documentation using GitBuilding - a software for documenting hardware. We will continue to document software according to specific software documentation standards like JavaDocs or instance. We will use established Unit Testing frameworks like Junit for instance.

12. How will your project address GOSH’s values of diversity and inclusion?

The very essence of the project is to create a system that will end exclusion for biology and health researchers around the world. They currently cannot afford to perform the research.

This is a meaningful, multi disciplinary, accessible project that include participation of marginalized populations. We are promoting and actively seeking the incorporation of new other members regardless of their social, economical strata, age, racial or gender identities.

13. Are there any conflicts of interest that you wish to declare?

None

14. Describe your experimental plan, including any new technologies or tools to be developed.

This is not a new project or just a general interesting idea to be implemented. We have already produced concrete, available, demo ready implementations both in the hardware, software and genetic engineering field. We need to complete the steps necessary to harden the system to industry standards. That means enhance, test, calibrate and document so it can really be a reliable and successful tool in the hands of the users. We don’t want to release a half baked product that will disappoint the users. As with any early version systems we have list of improvements to make the current system more robust. We want to improve the mechanical design so the system is quieter and could resist falls and accidental impacts. We want to run endurance tests and address the findings with corrections and enhancements. We want to enhance the current software web interface using WebSockes for real-time update graphs and improve on remote control capabilities. We want to add a real time optical density reader via a low cell. Both the optical density reader and flow cell of these have already been designed, built and unit tested separately but we need to incorporate them in the system.

We want to test a different type of motors with incorporated reduction gear that can deliver a much higher torque.

We want to make custom silicon lids and improve the attachment system.

We want to engineer and produce three new organisms to make possible an additional less expensive purification strategy. We need to perform a series of runs to quantify quality o the products, tune the protocols and include them as a la carte protocols in the software. We want to add a DO (Dissolved Oxygen reader) feature necessary for some types of mammalian cells. We already designed, fabricated and populated a custom PCB for this yet we need to fabricate and test the probe and integrate it in the system.

Design new immuno based product tests

Attempt to add a visual programming drag and drop interface or custom protocol creation similar to mBlock etc.

15. How will the work you describe be performed within the budget and time period allocated for the initial Phase I award? This should include project work time, ramp up and required reporting.

1 April to 1 March

Mechanical designs for attaching the high torque motors

Design the new plasmids and acquire the reagents for genetic engineering

Design the probe for Oxygen sensor

Design subsequent versions and order new PCB

Design the molds for silicone

Research into options for ESP32 embedded visual programming

Find out what additional candidate labs would be interested to install and test the device in the field. Initiate contact.

Add firmware improvements including WebSockets and WiFi capability hardening

1 March to 1 April

Build the probe for Oxygen sensor and perform unit tests

Poor, test and iterate through versions of the custom silicone lid

Populate new version additional PCBs and install firmware

Install OD meter and flow cell

Cut and mechanical assembly of several prototypes with the high torque motors

Acquire additional resources for genetic engineering

Establish and strengthen collaboration with candidate labs and initiate plans for the deployment and field testing of the device

1 April to 1 March

Genetic engineering for an additional construct to support silica binding

Test the new construct

Test the silicone lid with an inexpensive commercial container as a specialized alternative to off the shelf silicone bags

Fully integrate the dissolved oxygen monitoring

Order the necessary materials to support silica based extraction

Update the software to read and display the Dissolved Oxygen

Create and start implementing communication plans for presentation of the device

1 March to 1 April

Add a version of custom building of new protocols either using JSON files or - if possible, using visual programming

Genetic engineering for two additional constructs

Restructure documentation

Start calibration

Test silica based extraction

Start integration testing phase

Close communication and scheduled periodic meetings with candidate labs

1 April to 1 May

Start presenting the new device to external gatherings like conferences

Scheduled meetings with candidate labs on deployment and field testing of the device

Complete most of the calibration

Document the calibration

Create formal presentations

Perform integration testing phase

Perform endurance testing

Perform reliability testing

Document the findings

Make sure the procedure does not generate waste and test that all components are fully reusable

Multiple iterations of improving the device

Start implementing plans for the deployment and field testing of the device

Enroll and inform more early adopters and community

1 May to 1 June

Presenting the enhanced device to external gatherings

Multiple iterations of improving the device

Iterative tests of the products

Write and install in the firmware protocols for the new constructs

Start implementing plans for the deployment and field testing of the device

Start sending prototypes to field collaboration and getting early feedback

Start training field collaborators

Start testing the produced products in specific applications like LAMP for instance

Close communication with candidate labs and start deployment of the device

1 June to 5 July

Complete documentation

Continue training of new field collaborators

Deployment in the field labs

Support field researches

Continue to present the enhanced device to external gatherings

Multiple iterations of improving the device

Redeploy patches where necessary

Field test will result in supplementary findings in all the aspects of the device

Perform enhancements and modifications as a result of field test

Presenting the enhanced device to external gatherings and start co-opting new field labs and collaborators

Detailed plans for further enhancements

16. What essential milestones will you generate during your Phase I award?

Produce a working bioreactor with motion, temperature, optical density monitoring

Perform multiple types of testing, calibration and characterization of the system

Add three more essential constructs

17. If Phase I is successfully completed, what are the next steps?

Add CO2 control to the environment

Test with advanced types of cells

Add production of antibodies

Add production of drug delivery systems

Investigate and design production of CAR T Cell therapy components using the device

Design and run immuno based product tests

Create manufacture ready prototypes for kits

Research production of fully assembled devices

Add several more essential enzyme products to the existing list of three products by using off-patent enzymes from FreeGenes foundation

18. Please include a brief breakdown of allowable direct costs under the following categories:

Supplies

2200, Needed or building the devices and the new components

Electronic components and PCB assembly

Mechanical parts

Raw materials

Reagents

Lab consumables

Other consumables

Subcontracts

600, Review, validate and suggest changes. Expert Consultants

Travel

600, Travel for the volunteers and shipping costs, Travel for the volunteers.

Shipping costs

Other expenses (equipment etc)

500, Needed for testing, calibration, etc

QA testing equipment, Instrumentation, etc