1. Name of applicant(s)

Francisco Javier Quero

Urs Gaudenz

Smitha S Hegde

Marc Dusseiller

Shingo Hisakawa

Ganga Chinna Rao Devarapu

Harry Akligoh

2. Email address (or preferred and reliable way of official contact)

3. What track are you applying to?

Established Project Track

4. Tell us about your project in one or two sentences

Affordability and accessibility are the two main existing challenges that are limiting the global use of real-time nucleic acid amplification test (RT-NAAT) for infectious disease diagnosis for human health and agriculture; water purity testing; teaching and research purpose; GMO detection or personal health for home-testing. We aim to bridge this gap by developing an open-source, <50$ RT-NAAT that is easy to replicate without black-boxes, simple to use and accessible to every corner of the world.

5. Describe your project goals and how you expect to achieve them

Quantitative RT-NAAT is the gold standard for the detection of genetic material for various purposes. Although a decade has passed since the first open-source thermocyclers designs, RT-NAAT is still withstanding to arrive into the open-source panorama and hence, also limited its application for disease detection and management, especially in low and middle-income countries (LMIC). The few existing designs (f.e https://www.chaibio.com) still range in the order of thousands of dollars. With a decrease in price and improved accessibility, the significant impact of these technologies is huge and spread around fields such as infectious disease diagnosis, personal diagnostics, environmental or food testing and water purity analysis. We aim to fill this gap by developing an affordable, easily accessible, open-source RT-NAAT device and hope that it can be a future alternative at point-of-care (POC) testing centres, schools and research institutes.

We here count on our several years of experience in developing low-cost (<1$), open-source, self-sustainable NAAT based on LAMP, an isothermal amplification technology that is rapid and highly sensitive. We have demonstrated this for detecting various targets like Sars-Cov-2 (https://www.ncbi.nlm.nih.gov/pmc/articles/PMC8730511/), GMO (https://gmodetective.com/), typhoid (CRISPR-TyphoidDx – Open Bioeconomy Lab) and were also tested with clinical samples in LMIC, promoting its selection as a semifinalist in the Rapid COVID Testing XPRIZE (The XPRIZE Rapid Covid Testing challenge selects ‘Corona Detective’ and 3 other projects on Just One Giant Lab as semi-finalists | by Marianna Limas | JustOneGiantLab | Medium). Application of this technology will be at the base of the hardware design, which will carry the isothermal incubation while reading the resulting fluorescence signal in real-time.

In this project, we rely on the extensive experiences of the applicants who are pioneers in developing open-source PCR hardware (pocketPCR, ninjaPCR/qPCR) and a newly developed prototype for RT-LAMP. We combine the device design from these prototypes to build a quantitative LAMP (qLAMP) device that is also compatible with any isothermal amplification reaction (see Figure1). In order to reduce the time for design reviewing and rapidly prototype, we here will employ a hackathon-like approach, where a ten days residence at the Learning Planet Institute (LPI), Paris, will be organised for the experts to come together.

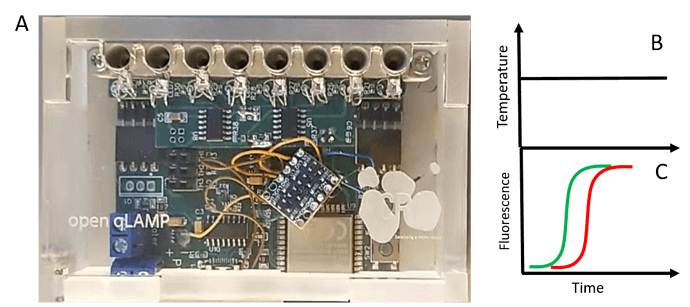

Figure1. (A) Prototype of an existing qLAMP device that we have previously developed. The prototype incubates the 8 reactions at a (B) constant temperature of 65ºC while reading the (C) resulting fluorescence signal in real-time. The device can also be controlled by a phone or computer through the local network to carry out protocols and record real-time signals.

During Phase I of this project, we do not anticipate sourcing any professional experts, as the applicants have several years of experience in the development of open-source hardware. However, during the next Phase of the project, we will seek professional experts from trusted manufacturer companies experienced in scaling open-source hardware models (Seeedstudio, Shenzhen) to produce the first batches of the technology. We will also distribute the hardware to our collaborators (Open Bioeconomy Lab, UK; Mboalab, Cameroon; HivebioLab, Ghana) to test the expected performances and its applicability with the end-users.

6. Approximately how many people would be working on your project?

For phase I, the main core of the project consists of seven researchers from Switzerland, Paris, Japan, Ireland and UK that will work in the hardware designs. During Phase II we will work with a broader team of professional experts in large scale manufacturing solutions and local partners located in LMIC that will study the applicability of the designs.

7. Describe how your organisation will create and manage collaboration with others.

Centred around the core principle of building a global alliance of educational stakeholders to empower learning for better future, LPI has worked for several years on collaborative open-source projects, including isothermal amplifications (Projects) and open-source medical devices. It also boasts infrastructure and experience in hosting workshops, hackathons and conferences. Based on a long experience in hosting project-based learning, LPI has established itself as a relevant community for disseminating knowledge to the residents, maximising the impact and reaching new possible partners. These work ethics and infrastructure of LPI will hence enable us to build an open-source network to increase the accessibility of the device globally.

8. Does your project have representation for a marginalized demographic due to factors such as race, ability, place of birth, gender, sexual orientation, socioeconomic class situation or other identification? If so, how?

Quantitative real-time DNA amplification is at the heart of either diagnosing infectious disease or any section of biology research. Use of these devices has been limited due its cost and availability, therefore, refuting to elaborate and end-point methods like gel-electrophoresis. This project will change accessibility and affordability of this device to specially low-income countries either for POC or teaching purposes. Furthermore, the core of the project includes researchers and collaborators from diverse geographical backgrounds, professional expertise and socioeconomic origins, either at the development stage or at the end-user level at the next phases.

9. What resources/infrastructure do you currently have to support your project?

LPI counts with a fully equipped MakerLab with standard digital fabrication equipment (Laser cutters, FDM and SLA 3D printers, wood and metal CNCs, fully equipped electronics prototyping station etc) and fully functional wetlabs with all the necessary standard molecular biology equipment and essential reagents. During the ten days residency and following that, both these spaces will be accessible to the applicants that could speed-up the prototype reviewing, testing and calibrating. The Institute has also experience in hosting several science and community events that will be helpful in hosting this ten day residency event to cover within the budget of the project. Fran Quero, applicant of this project, has been also working towards producing self-sustainable, low-cost enzymes and reagents for LAMP test at LPI, these resources will be used in this project for device measurements and also testing at later stages of the project.

10. What will you use the funds for? Describe your budget. List what you are going to spend it on and how.

As detailed in Section 18, the budget will be distributed to organise a ten-day workshop at the LPI and the raw materials necessary for design review and modifications. As the applicants are based in the UK, various parts of Europe and Japan, a part of the budget will support the hosting cost, travel and subsistence cost of the applicants in Institute’s budget accommodation or Airbnb. With the kind cost support from the Institute’s existing Makerlab and wet lab facilities, the second part of the funding will be dedicated to securing raw materials like 3D printing filaments, PCB, electronics and components for optics. Additional costs to travel or accommodation that are not covered by this grant will be funded by an applicant’s (Urs Gaudenz) additional travel budget from Shuttleworth Foundation (5000$).

11. How will you share the outcomes of your project? What documentation will you provide so that it will benefit the community as a whole? (videos? photos? a how-to?)

The outcomes, detailed device design, assembly, safety guidelines and operational protocol will be documented elaborately in WiKi with photos and videos.

12. How will your project address GOSH’s values of diversity and inclusion?

As an outcome of the project, an open-source and low-cost device will be produced or distributed at a nominal cost to anyone, at any part of the world. This bridges some of the gaps in affordable diagnostics for human health, research and training purposes for an equitable future.

13. Are there any conflicts of interest that you wish to declare?

The current project builds further on the open qLAMP that was previously developed in collaboration with Jenny Molloy, Open Bioeconomy Lab, who has been the Co-PI on the project (follow the link to see the project design: https://gitlab.com/open-bioeconomy-lab/diagnostics-hardware/rt-lamp-device) and who has a conflict of interest as a Director of GOSH Inc, the organisation that is administering the funding. The members of the open qLAMP project are also the applicants in the current proposal but Jenny was not involved in the conception, design or drafting of this proposal and will not receive any funding or other direct support from the grant if awarded. Her lab may receive prototypes for testing in line with all other collaborators.

14. Describe your experimental plan, including any new technologies or tools to be developed.

The proposed work plan for this project will build on the existing open qLAMP prototype (Figure 1) to include an improved detection approach based on the knowledge from previous open source devices of the applicants like pocketPCR and ninjaPCR. The design will consider replacing the existing photodiodes with low-cost cameras, optical waveguides that can improve the sensitivity of detection, improved signal-to-noise ratio, long operational life, highly robust designs, component availability and reduced cost of production. The device will be built to detect the fluorescence signal from dyes like SYBR, Syto dyes and probes like FAM and Alex, which have different quantum yields and working concentration range. It will also be tested to maintain isothermal incubation temperature necessary for LAMP (65℃) and also its extensibility to other isothermal amplification techniques like RPA,(37℃), CRISPR-Cas detection temperature (45-55℃) and thermocycling for PCR, if need be.

15. How will the work you describe be performed within the budget and time period allocated for the initial Phase I award?

This should include project work time, ramp up and required reporting.

(i) During the first session of the project (April), at the LPI, a low-cost lyophilized LAMP reaction with the existing reagents and protocol will be prepared that can be used for several rounds of testing and calibration. The applicants will meet online to review the designs of various existing devices that will be used during the residency and necessary essential raw materials needed for rapid review and design will be ordered to the Institute. During this session, travel tickets, hosting formalities will be completed.

(ii)The second session (May) of the project covers the ten day marathon (excluding the travel time) and the necessary set-up of the Makerslab for the event. The residents will use the first half of the residency time to experiment, review, construct functional prototypes using technologies like digital manufacturing and open source prototyping electronics. In the second half of the residency, the final prototype will be tested using the wetlab resources for its performance like temperature stability, fluorescence signal sensitivity and robustness.

(iii)In the final session of the project (June): a detailed device design, necessary assembly and testing protocols with photos and video demonstration will be documented for open use. The cost of production will be reviewed and prepared for the next mass production and distribution Phase. Various manufacturing techniques such as mould extrusion, large scale PCB assembly, quality assessment will be discussed and reviewed with various vendors (new and previous projects).

16. What essential milestones will you generate during your Phase I award?

Milestone1: By the end of the session 2 of the project, a functional, low-cost (<100$) qLAMP device that is compatible with various fluorescence dyes and probes, to in-house and commercial LAMP reagents. Milestone2: Towards the end of the project, we aim to complete all the above mentioned documentation to make the design open-source.

17. If Phase I is successfully completed, what are the next steps?

During Phase II, we will work to produce and deploy the device (see Figure 2) for research labs and POCs in LMIC with limited accessibility to other devices.

We will adapt the prototype to standard industry manufacturing techniques (mould extrusion, large scale PCB assembly etc) together with a professional expert panel in large scale manufacturing (SeeedStudio, Shenzhen; Tsinghua University, Shenzhen Campus).

For the applicability, we will work together with local partners (Mboalab, Cameroon; HivebioLab,Ghana) to test the system under real situations. The system will be tested for targets like SARS-CoV-2 in clinical samples (using above mentioned Corona Detective), typhoid detection (CRISPR-TyphoidDx,Open Bioeconomy Lab) and many more.

18. Please include a brief breakdown of allowable direct costs under the following categories: personnel, supplies, subcontracts, travel, and other expenses (equipment).

| Cost category | Details | Unitary Cost (USD) | Quantity | Estimated total cost (USD) |

|---|---|---|---|---|

| Travel cost | Travel to Learning Planet Insitute for the 10 day residency | |||

| Transportation within Paris | Commute within Paris for 5 participants | 100 | 5 persons | 500 |

| Flights to Paris | Transportation from European researchers hometowns to Paris | 400 | 4 persons | 1600 |

| International Flights | Transportation from Non-European researchers hometowns to Paris | 700 | 1 person | 700 |

| Hosting | Accommodation and subsistence for 5 participants | |||

| Accommodation | budget accommodation like Airbnb | 700 | 5 persons | 3500 |

| Food | 30$ per day | 300 | 5 persons | 1500 |

| Materials expenses | Materials cost for rapid prototyping | |||

| 3D printing materials | ABS, PETG and PLA filaments for FDM printers and resin for SLA printers | 300 | - | 300 |

| Optics | Camera, waveguide, fluorescence filters | 400 | - | 400 |

| Electronics | PCB, solder, integrated circuits, photodiodes… | 500 | - | 500 |

| Laser cutter materials | Cardboard for prototyping and acrylic sheets | 200 | - | 200 |

| Lab consumables | Pipette tips, tubes, eppendorfs | 500 | - | 500 |

| LAMP reaction reagents | Lyophilized LAMP reactions prepared by LPI | 500 | - | 500 |

| Management Expenses | Expense towards running cost of the residency | |||

| LPI budget management | LPI budget management expenses % of the received money from GOSH. | 368 | - | 368 |

| Makerspace and WetLabs management expenses | Lab manager from LPI to coordinate the residency event | 200 | 10 days | 2000 |

| Total Cost | 12568 | |||

| Additional sources of funding | ||||

| Cost covered by LPI | Wetlab materials, lab manager cost and Makerspace cost | 3000 | ||

| Additional travel grant | Covered by an applicant’s Shuttleworth foundation towards travel | 5000 | ||

| Final cost covered by GOSH funding | 4568 |