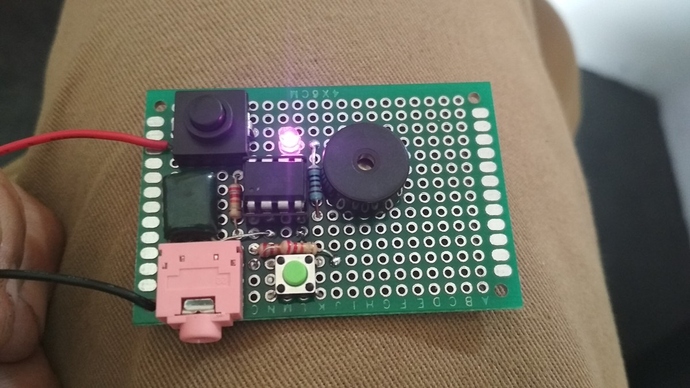

Great approach. We have also developed this ultra simple and low cost version of our Attiny sensor boards. aka 8Bit Mixtape aka CocoMake7, with a similar approach. it doesnt even need an “arduino”, the Attiny85 is widely available, it can be re-programmed using an audio signal (no drivers needed, and communicate to an app through mini-jack) and also has USB-HID capability for sending numbers as keyboard." 234".

A true open hardware project should be easy to redesign, repurpose etc. and not rely on buying dedicated boards.

But the same board can still be made with custom PCB for a workshop and souvenir. can save time during the session.

See this: